Record Store Day is usually 'the one day each year when over 200 independent record shops all across the UK come together to celebrate their unique culture. Special vinyl releases are made exclusively for the day, in what’s become one of the biggest annual events on the music calendar.' This year, due to COVID-19, Record Store Day is being split across 3 dates: 29th August, 26th September and 24th October.

This Record Store Day, Saturday 29th August 2020, is particularly exciting for Greatbear as it sees the release on Vinyl Revival, Manchester of The High - Martin Hannett Sessions, a restoration and digitisation project we worked on earlier this year.

Martin Hannett - Manchester music producer, known for his era-defining creative work with Buzzcocks, Joy Division, New Order, John Cooper Clarke, The Stone Roses, Happy Mondays and many others - died aged 42 in April 1991.

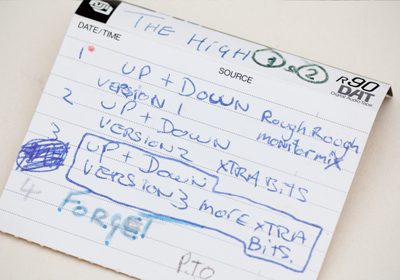

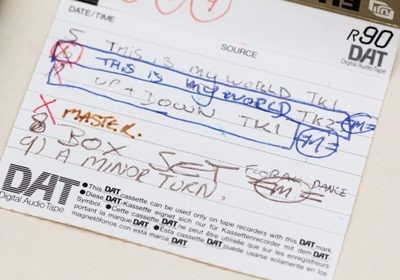

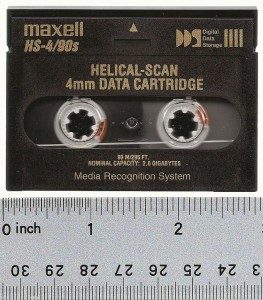

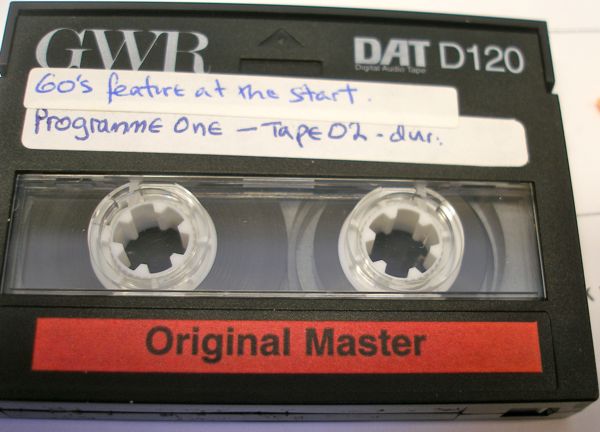

The tapes we received were DAT (Digital Audio Tape) masters, produced by Hannett at recording sessions with The High in 1989 (at Strawberry Studios) and 1991 (at Great Linford Manor), and included Hannett's last production work before his untimely death.

The High were formed in 1989 by former Turning Blue singer John Matthews and former Buzzcocks F.O.C. members Andy Couzens (guitar, also formerly of The Stone Roses and pre-Roses bands The Patrol and Waterfront), Simon Davies (bass), and drummer Chris Goodwin (also formerly of the Waterfront as well as the Inspiral Carpets). They were signed by London Records and had three UK Singles Chart hits in 1990 before breaking into the top 30 in 1991 with a revamped version of their debut single, the Martin Hannett-produced "Box Set Go".

analogue to digital

From the Nigel Couzens footage (see video clip below), it looks like the Strawberry Studios sessions were recorded to 2 inch analogue tape, on a 24 track Studer A80. This was quite an old machine at that time as there would have been the A800 and possibly the A820 available too - but maybe they just loved the sound on the A80.

DAT, introduced by Sony in 1987, became popular in the audio and recording industry for mastering during the 1990s. The initial recordings would be made to 2" (or other width) analogue tape, but the mixed and produced final versions would be recorded to DAT - allowing the benefits of lossless encoding and avoiding the addition of further analogue tape hiss at the mastering stage. This process could be seen as a stepping stone towards an emerging all-digital production chain, and the development of hard disk recording.

fragile tape

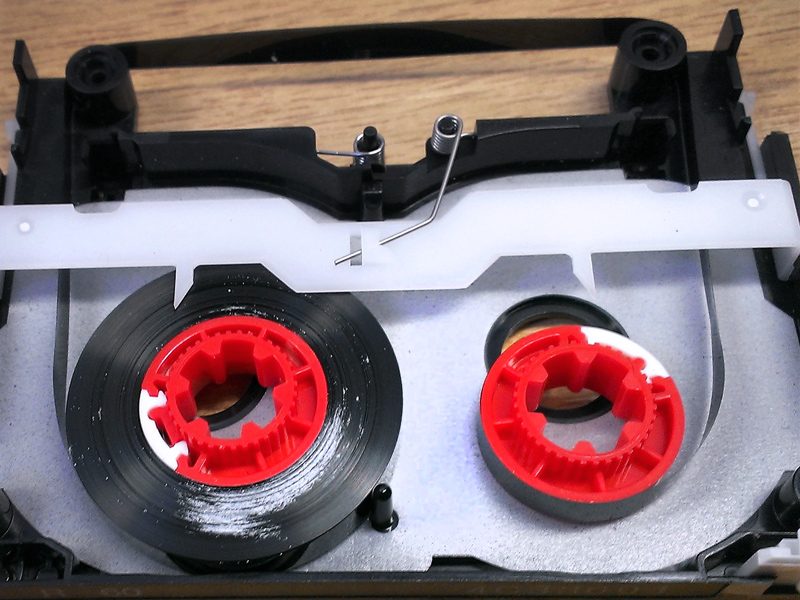

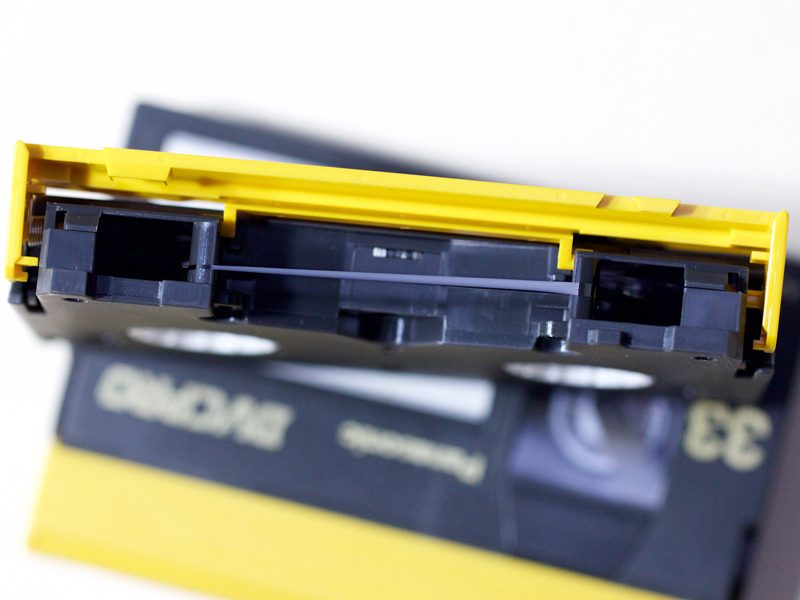

At 3.81mm wide and 0.013mm thick, DAT is more fragile than other cassette-based digital tape formats such as DTRS/DA-88, ADAT and PCM digital audio, or any of the reel-to-reel formats (analogue or digital).

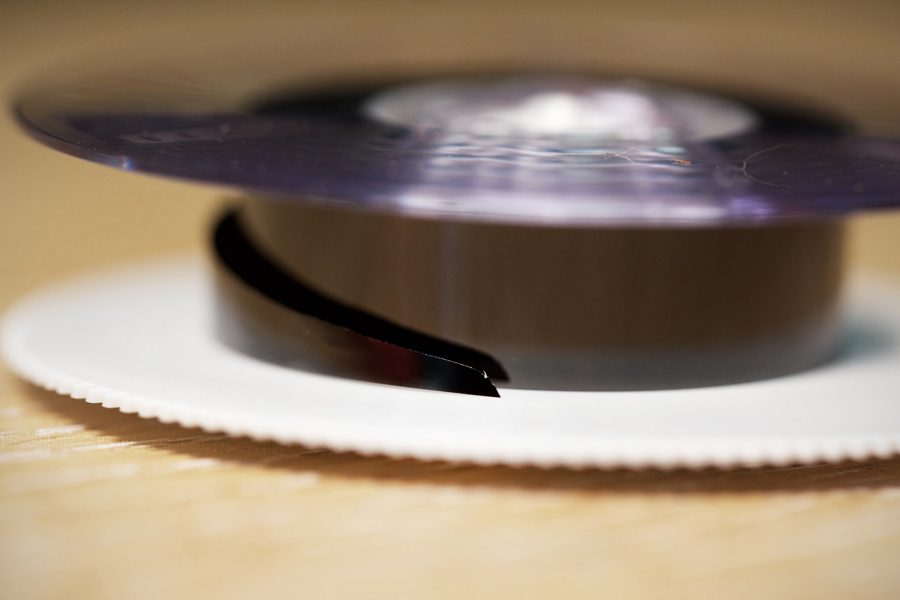

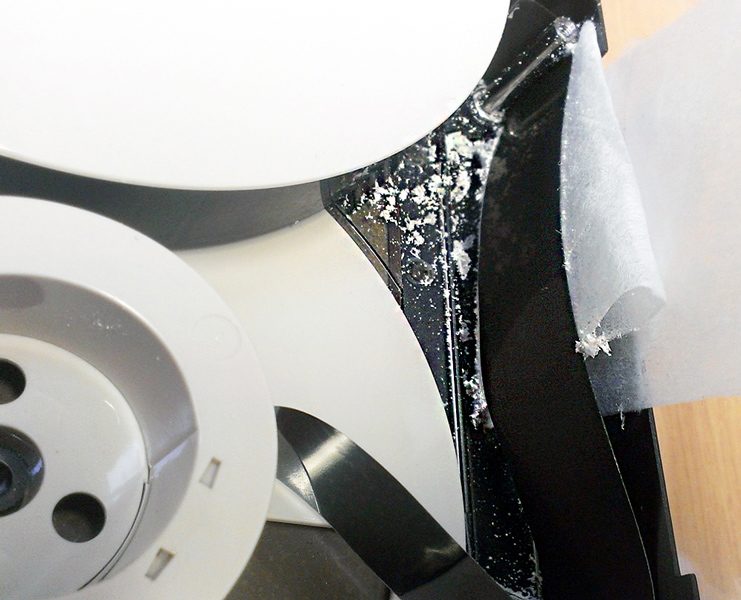

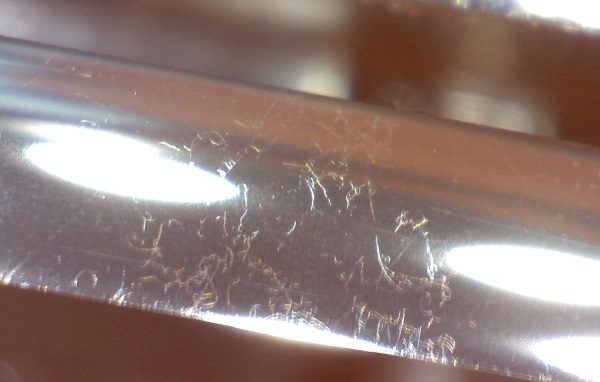

This makes it vulnerable to ripping. The High - Martin Hannett Sessions DAT masters arrived at Greatbear with visible signs of mould growth along the edges of the tape. (See the fuzzy white threads along the surface of the tape pack in the pictures above and below.) When this happens, the mould sticks the layers of the tape together - particularly along the edges - which inevitably leads to the tape ripping under the high tension of playback.

A ripped tape is especially problematic because DAT uses a helical scan recording system, based on a miniature video transport, and so cannot be spliced for clean edits. (Splices also risk irreparable damage to heads on the drum of the playback machine.) A ripped DAT tape - the helically-imprinted signal being bisected - results in irreversible signal loss.

restoration

We've found the safest way to restore mould-stricken DAT cassettes to a playable state and avoid ripping is to:

- Acclimatise the tape to the controlled temperature and humidity of the Greatbear studio, driving the mould spores to dormancy

- Disassemble the cassette shell

- Very slowly and carefully unwind and rewind the tape by hand, dislodging the 'sticky' mould

- Re-house the spools in a new, clean shell

- Digitise via multiple passes, cleaning the DAT machine between plays. For these tapes we used our Sony PCM 7040

Sony ceased production of new DAT machines in 2005, and working, professional machines are becoming rare. We spend a considerable (and usually enjoyable) amount of time and resources keeping our machines in good condition. The Sony PCM 7040 is one of the better DAT machines in terms of the robustness of the tape transport and machine parts availability, as the same transport system was used in many Sony DDS DAT drives used in computer backup.

The problem of mould growth on DATs is not unique to these precious Hannett / The High recordings.

Most DATs are now between 20 - 30 years old, and it only takes one period of storage at high temperature and/or relative humidity (RH) for mould to set in. To avoid damage, magnetic tape must be stored consistently at levels of 18 - 21 °C, and at 45 - 50% RH - something which no garage, attic or back room can guarantee...

We regularly receive mouldy DATs at the Greatbear studio. So much important material was mastered to DAT in the 1990s, and its vulnerabilities make it a priority for digitisation.

Support your local independent record shop on Record Store Day and every day!

Transfer your Digital Audio Tapes (DATs) to a stable format!